Published online by Cambridge University Press: 25 November 2024

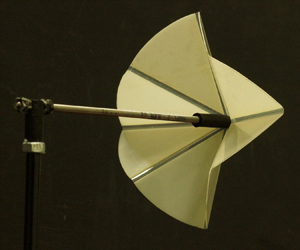

We leverage the snap-through response of a bistable origami mechanism to induce a discontinuous evolution of drag with flow speed. The transition between equilibrium states is actuated passively by airflow, and we demonstrate that large shape reconfiguration over a small increment of flow velocity leads to a pronounced and sudden drop in drag. Moreover, we show that systematically varying the geometrical and mechanical properties of the origami unit enables the tuning of this drag discontinuity and the critical speed and loading at which it occurs. Experimental results are supported by a theoretical aeroelastic model, which further guides inverse design to identify the combination of structural origami parameters for targeted drag collapse. This approach sheds light on harnessing origami-inspired mechanisms for efficient passive drag control in a fluid environment, applicable for load alleviation or situations requiring swift transitions in aerodynamic performances.